Rooter X3000

How many free memories can I set parameters on my Rooter® X3000?

The device contains 10 programmable free memories (M0 M9), any operating mode (CW, CCW, REC, ATR, EAL) can be selected.

Can I connect an external apex locator to my Rooter® X3000?

The Rooter® X3000 has an embedded apex locator

Can I adjust the volume of the beeper?

The device sound volume can be adjusted to 4 different sound levels (Vol. 1 to Vol. 4), and the sound volume can also be muted (Vol. 0).

Does the Rooter® X3000 can be used with other reciprocating files systems than R Motion?

The device contains 10 programmable free memories, each of them can be programmed for reciprocal operation mode and can be set to a variety of reciprocating angles and speeds to meet all current reciprocating motion requirements.

- In REC mode, the working speed can be adjusted for 100rpm to 500rpm (50rpm increments).

– In REC mode, the Forward Angle can be adjusted from 20 to 400 °°(10 increments) and the Reverse Angle can be adjusted from 20 to 400 °°(10 increments).

What is the weight of the handpiece with contra-angle?

The weight of the handpiece and contra angle is 157 grams.

What is the technology of the mini motor integrated in the Rooter® X3000?

It is a brushless motor.

Does the Rooter® X3000 have an “Automatic Power Off” function?

In stand by state, the device automatically turns OFF after the set timer. The timer can be adjusted from 3 minutes to 30 minutes (1 minute increments).

When fully charged, how long can I use the unit?

Time may vary depending on the usage. The battery capacity is 2000mAh.

How long does it take to fully charge my Rooter® X3000?

The required time to fully charge the Rooter® X3000 is ~ 285 minutes.

How often should I calibrate the device?

The motor must be calibrated before the first use and after replacement or lubrification of the contra angle.

Does the Rooter® X3000 has an “Apical Auto Reverse” function?

Yes, the motor automatically reverses the rotation direction when the file reaches the reference point set by the user. The motor goes back automatically to initial rotation direction when the file is pulled away from the reference point.

What are the features of the original contra-angle?

It is a 4,7:1 contra angle offering 360 rotation.

Can I use another contra-angle than the original one?

FKG does not recommend to use of other contra angle with the Rooter® X3000 endo motor than genuine ones.

How do I clean, disinfect and sterilize the Rooter® X3000 components?

Please consult the user manual for any questions relating to cleaning, disinfection and sterilization of the Rooter® X3000 components.

R-Motion

1 - What’s the reason for your claim to be the safest product on the market?

Endo file breaks in the tooth occur notably due to cyclic fatigue, the effort caused by repeated use. Tests carried out by our in-house labs show that our files withstand cyclic fatigue up to 3.6x more when compared with equivalent competitors' instruments. This quality and resistance is due to the unique design of our products as well as the very high-quality criteria to which we submit them. (Swiss Quality FKG)

2 - You talk about a minimally invasive approach, why is that important?

The practice of endo has always been focused on lessening the impact of tooth interventions. FKG has become synonymous with this approach. For R-motion®, and all of our other mechanized root canal preparation systems, we use a unique blend of technology and design that allows our files to be thin, agile and resistant.

3 - You now have a range of 7 files, isn't that too long to use?

For most cases, we recommend a sequence of just two files: The R-Motion Glider and the RMotion 25 or R-Motion 30 file – it all depends on your therapeutic approach. In unusual cases (calcified canals, narrow canals, wide canals,...), you may need more choice, hence the full range of files.

4 - Which parameters should be applied to R-Motion®(angles & speed)?

R-Motion® files have been designed and can be used with standard reciprocating modes in existing motors (CCW >> CW).

FKG has in its range 2 references of latest generation endomotors, cordless and with integrated apex locator, both with a preset program dedicated to R-Motion® files: The Rooter® Universal and the Rooter® X3000

For more information about this new endomotors, please contact your local FKG dealer or consult our website.

5 - Can I use R-Motion® files on OTR (Optimum Torque Reverse) motion?

OTR motion is not recommended by FKG for the use of R-Motion® files.

6 - What is the metallurgy of R-Motion® and how does it affect the treatment?

All R-Motion® instruments are made of a medical grade NiTi alloy. The active part of the instrument undergoes a proprietary heat treatment that triggers the austenite finish temperature (Af) just below body temperature, between 32° and 35°C.

7 - Does R-Motion® have constant or variable taper ?

R-Motion® Glider has a taper of 3% from the tip to 9mm, then 6%.

R-Motion® shaping files have a constant taper.

8 - Which cross section for R-Motion®?

Rounded triangular symmetrical cross-section in all instruments.

9 - Does sterilization affect the metallurgical properties of R-Motion® files ?

The sterilization has no effect on the metallurgical properties of R-Motion® files.

10 - What is the process used by FKG to reduce micro-surface defects on R-Motion® files?

It is a proprietary electrochemical polishing. The treatment removes surface imperfections, reducing drastically the risk of weak points (micro-cracks). The resulting shiny surface also allows for better cleaning.

Furthermore, this process makes it possible to obtain increased resistance to fatigue and corrosion.

11 - In some clinical cases, I have the impression that the bluish color of my R-Motion® files changes slightly. Why, and what could be the impact on files' properties?

It is possible that the optical properties of the oxide surface layer may vary slightly after root canal treatment or after autoclavation, but this does not affect the properties of the alloy in any way, it is only something of aesthetics.

So, no worries you can continue to use the files.

12 - Under which circumstances should I use the R-Motion® Glider C?

Use of the R-Motion® Glider C is recommended for canals which require an instrument with more rigidity, and/or if the R-Motion® Glider is no longer progressing and can not reach the working length.

13 - Under which circumstances should I use the R-Motion® 20?

Use of R-Motion® 20 is recommended to shape small/narrow canals.

14 - Is R-Motion® recommended for retreatment?

R-Motion® has not been validated for retreatment cases and therefore cannot be recommended for this indication. FKG recommends using its existing dedicated systems: XP-endo Retreatment or D-Race.

RACE EVO

1 - What is the metallurgy of RACE® EVO and how does it affect the treatment?

All RACE® EVO instruments are made of a medical grade NiTi alloy. The active part of the instrument undergoes a proprietary heat treatment that triggers a phase transition (between martensite and austenite) just below body temperature, between 32°and 35°C.

2 - What is the impact of this new metallurgy on the cutting efficiency of RACE® EVO 4% sequence and RACE® EVO 6% sequence instruments?

The heat treatment does not have a direct influence on the cutting efficiency, it is rather the legacy RaCe design associated with the higher rotation speed (1’000 rpm) that improves the cutting efficiency, by up to 50% compared to former RaCe product lines.

3 - What are the resistance to cyclic fatigue and torsional resistance of RACE® EVO 4% sequence and RACE® EVO 6% sequence instruments?

RACE® EVO 4% sequence and RACE® EVO 6% sequence instruments show up to 2.8 times higher resistance to cyclic fatigue and up to 1.9 times higher resistance to torsion.

4 - Why is RACE® EVO designed with a safety tip rather than with a booster or active tip?

RACE® EVO’s unique rounded safety tip allows for an efficient progression of the instrument along the canal.

5 - Why is it not necessary to have an intermediate file between the rotary glide path file (15/.04) and the initial shaping file (25/.04)?

Thanks to the combination of heat treatment, design and higher speed, an intermediate file is not necessary. You will be convinced when you try it !

6 - How many root canals can I treat with a RACE® EVO instrument?

With any RACE® EVO instrument you can treat up to a maximum of 8 root canals. However, you still need to inspect the RACE® EVO instrument on a regular basis during use, and change if it shows any signs of deformation (for example: straightening). The good news is that RACE® EVO instruments, once they have reached the end of their service life, will deform in a visible way before they fracture. This warning is an additional safety feature specific to these instruments.

7 - Without SMD (SafetyMemoDisc), how can I know how many canals I treated?

SMD is not needed because RACE® EVO instruments show sufficient resistance to fatigue to guarantee a maximum use of 8 canals, no matter how difficult the curvatures are. However, if you feel more confident with SMD, they are still available separately in the FKG product assortment.

8 - Is there any risk if I use RACE® EVO instruments over 1’000 rpm?

To achieve full efficiency of RACE® EVO instruments, FKG recommends a speed of use between 800 and (ideally) 1'000 rpm. FKG cannot recommend the use of RACE® EVO instruments at higher or lower speeds.

9 - Is RACE® EVO recommended for retreatment?

RACE® EVO has not been validated for retreatment cases and therefore cannot be recommended for this indication. FKG recommends using its existing dedicated systems: XP-endo Retreatment or D-Race.

Rooter Universal

1 - How many free memories can I set parameters on my Rooter® Universal?

The device contains two user created file systems: “Rotary File” and “Recipro File”

Rotary File: 4 programmable free memories are available.

Recipro File: 1 programmable free memory is available.

2 - Can I connect an external apex locator to my Rooter® Universal?

The Rooter® Universal has an embedded apex locator.

3 - Can I adjust the volume of the beeper?

No, the volume of the beeper can’t be adjusted.

4 - What is the weight of the handpiece with contra-angle?

The weight of the handpiece and contra-angle is 150 grams. If used with the lighting device, please allow a few extra grams.

5 - What is the technology of the mini-motor integrated in the Rooter® Universal?

It is a DC motor.

6 - Does the Rooter® Universal have an “Automatic Power Off” function? And can I change its settings?

In stand-by state, the device automatically turns OFF after 3 minutes. This parameter can’t be changed.

7 - How long does it takes to fully-charge my Rooter® Universal?

The required time to fully charge the Rooter® Universal is ~ 120 minutes.

8 - When fully charged, how long can I use the unit?

Time may vary depending on the usage. The battery capacity is 1200mAh.

9 - How much time of work is left when only one bar is shown on the Rooter® Universal battery indicator?

It depends on the usage; it is recommended to charge the handpiece when it reaches the last bar of the battery charge level indicator.

10 - What technological generation is the apex locator?

The Rooter® Universal embeds a 6th generation apex locator.

11 - Does the Rooter® Universal has an “Apical Auto Reverse” function?

Yes, when the file reaches the apex position set by the user, the motor will automatically rotate in the reverse direction.

12 - What are the features of the original contra-angle?

It is a 16:1 contra-angle offering 360° rotation.

13 - Can I use another contra-angle than the original one?

FKG does not recommend to use of other contra-angle with the Rooter® Universal endo motor than genuine ones.

14 - How do I clean, disinfect and sterilize the Rooter® Universal components?

Please consult the user manual for any questions relating to cleaning, disinfection and sterilization of the Rooter® Universal components.

Speed & Torque - Recommendations

CI metal handle - Color codes

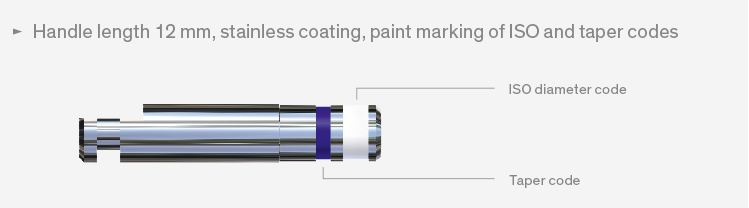

FKG rotary instruments are equipped with a CI metal handle, depth marks and a silicon endo stop.

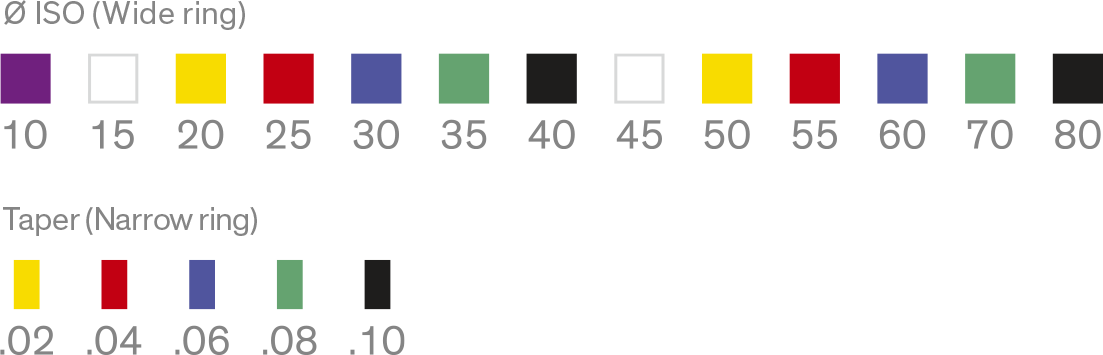

The aim is to provide easy identification of the ISO diameter (wide ring) and taper (narrow ring).

Color codes

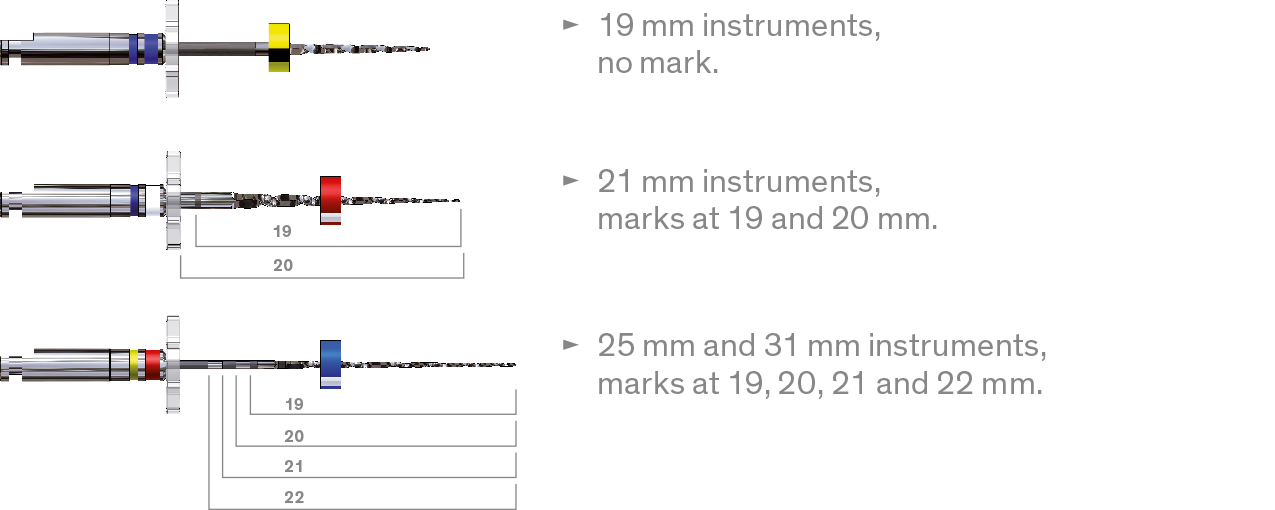

CI metal handles - Depth marks

The depth marks are used to recognise the position of the working length (WL) in the tooth and are additional to the endo stop. The depth marks are applied on all instruments in the XP-endo and Race ranges.

- Depth marks applied on instruments of length 21 mm/25 mm/31 mm

- Examples of instruments with depth marks:

Race - Golden rules for optimal use of Race instruments

- Speed: 600-1000 rpm - torque: 0.5 to 1.5 Ncm, depending on instruments see details.

- Broad back and forth movements without using force.

- Light hand, let the instrument do the work.

- Work for 3-4 seconds, remove.

- Clean the blade and irrigate the canal.

Race - How many times can a Race be used?

The following are the instructions for the SafetyMemoDisc:

- 1 petal corresponds to simple cases, that is, straight, slightly curved or wide canals.

- 2 petals correspond to moderately complex cases, that is, more curved or narrow canals.

- 4 petals correspond to complex cases, that is, canals with extreme curvature or S-shaped, very narrow or calcified canals.